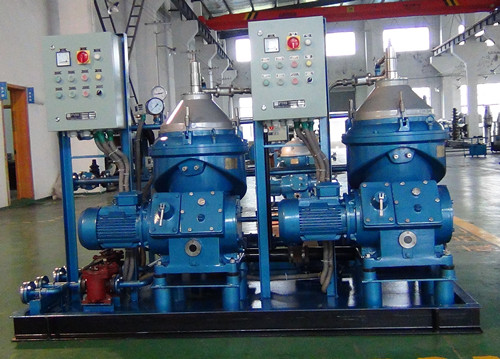

Decanter centrifuge is one of our main products. Utilizing our technological advantages, we have developed centrifuges with varied structures to cater for different sludge dewatering requirements.

In the field of environmental protection, we use the automatic control system that boasts high length-diameter ratio, high speed, small differential speed. High length-diameter ratio increases the material clarification and dewatering time inside the machine; high speed generates great centrifugal force, leading to thorough dehydration of material; small differential speed reduces spiral stirring the materials, increases the dewatering time, therefore improves the separation in sludge thickening, dewatering and clarification, which can obtain drier solid residue and clearer clarification liquid compared to other decanter centrifuges; in order to maintain the best dewatering effect, the operation parameters are subject to automatical regulation with the amount and quality of sludge entering into the centrifuge, which ensures normal operation of the machine and stable water content in the discharged sludge. If the condition of sludge entering the machine changes greatly, beyond the regulation capacity of the machine or the machine itself fails, the machine will shut down automatically and alarm.

Our centrifugal sludge dewatering machines can achieve sludge thickening, sludge dewatering as well as thickening and dewatering integration.

The sludge dewatering system consists of five parts: (1) Sludge feeding system, (2) Flocculant dosing system, 3) Thickening and dewatering system, (4) Mud cake delivery system, (5) Electronic control device of sets of system;

Thickening and dewatering of sludge arising from urban life, power plant, petrochemical refinery, coking as well as from industries.

Decanter Centrifuges technical parameters

|

Type |

Bowl diameter(mm) |

Bowl length/ Bowl diameter |

Bowl speed (r/min) |

Main Power(Kw) |

|

LW180 |

180 |

2.5-720 |

6000 |

3-5.5 |

|

LW260 |

260 |

3.0-4 |

5000 |

7.5-11 |

|

LW355 |

355 |

2-4.5 |

4000 |

11-30 |

|

LW420 |

420 |

3-4.1 |

3600 |

18.5-37 |

|

LW450 |

450 |

2-4.4 |

3600 |

18.5-37 |

|

LW480 |

480 |

2-4.2 |

3200 |

18.5-45 |

|

LW500 |

500 |

2-4.2 |

3200 |

18.5-55 |

|

LW530 |

530 |

2-4 |

3200 |

22-55 |

|

LW580 |

580 |

2-4 |

2800 |

30-55 |

|

LW620 |

620 |

2-4 |

2800 |

37-110 |

|

LW760 |

760 |

2-3.5 |

2500 |

55-132 |

|

Note: In case of differences between the table and the user manual, the latter shall prevail. |

||||